Product Designer and AI Enthusiast

LunchBook and

The Jug

Context

The lunch container project for schoolchildren aged 14-16 addresses poor dietary habits and space constraints in bags, promoting healthier eating and portion control. It requires a leakproof, microwave, and dishwasher-safe design, primarily made of polypropylene with a maximum wall thickness of 2.5 mm for easy carrying. Manufacturing should use 2 shot injection molding for sustainability, with a familiar yet appealing design that stands out in structure or concept.

The author’s role in this project has been to prototype, test materials for manufacturing and manage the entire project across all departments. Hence, the sections covered are the prototyping, heat testing, manufacturing and presentation stages.

The Brief

To develop an innovative lunchbox tailored for students aged 14-16, prioritizing health-conscious food choices and convenient packing mechanisms, while also incorporating appealing design elements that resonate with the target demographic's values.

Prototyping

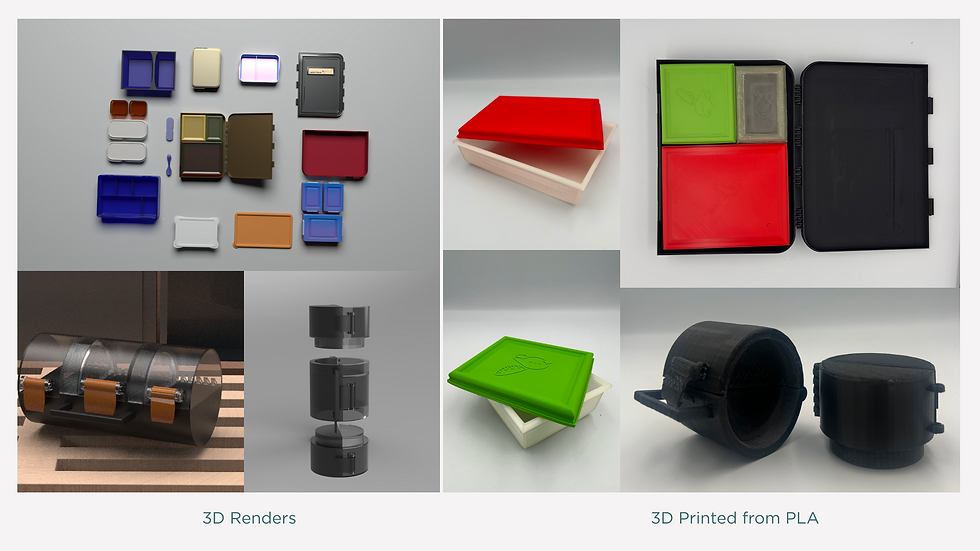

After finalizing the designs to two options, the team initiated CAD drawing and prototyping using Chemiwood, wood, and 3D printing to explore various locking mechanisms. Models for heat testing were printed using Epoxy Resin to guarantee suitable thermal conductivity. Finalizing dimensions for the two designs was crucial, informed by secondary research conducted in the problem space.

Some important decisions were made for the manufacturing specifications based on the following heat testing observations:

-

The heat dissipates faster with liquids

-

When some space is created, the heat dissipated from the box to the environment given the smaller size of the sample.

-

However, the heat does not get transferred to the other box.

-

The need for a double walled container does not arise due to the existing gap from the lids.

-

The thermal conductivity for Epoxy is quite close to that of Polypropylene and hence has similar heat dissipation properties.

-

The single-walled containers instead of the double-walled ones make manufacturing simpler and lesser in cost through single shot injection moulding.

Heat Testing

Manufacturing

This stage brought several challenges, especially with the printing process and model conversion. Troubleshooting problems occurred with machine availability, requiring a shift to older machines. Despite issues with sensors, nozzles, and beds, the team's improvisation taught valuable lessons in manufacturing processes.

The Final Output